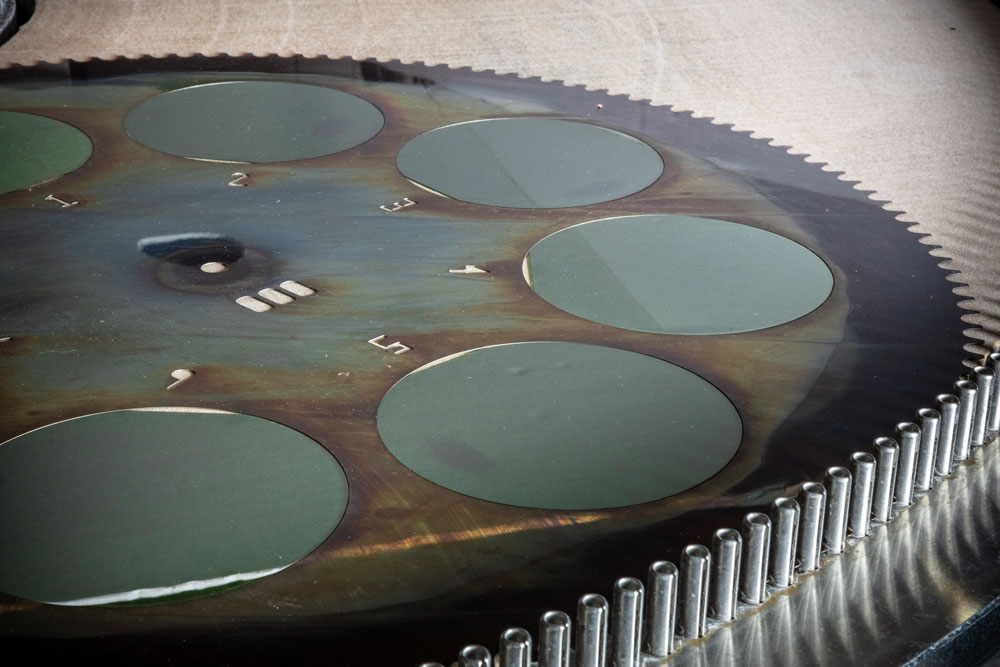

Carriers

High quality lapping, grinding, and polishing carriers are a key component to the success of every double-side process. Our knowledgeable worldwide sales team provides the technical support required to quickly offer customized solutions for all your double-side carrier requirements. We stock a complete line of carrier raw materials and semi-finished goods to provide consistent delivery of quality carriers that ensure your process stability and part quality.

Please contact PR Hoffman Machine Products to discuss your carrier requirements. We’ll work with you to design the optimum solution for your process, provide additional information, or answer any questions you may have.

Lapping, Polishing, and Grinding Carriers

We manufacture lapping carriers (also called workholders) for planetary lapping and polishing machines including those manufactured by P.R. Hoffman, Speedfam, Peter Wolters AG, Hamai, Somos, Fujikoshi, Strausbaugh, Melchiorre, Lanzhou, Lapmaster and other specialty machines adapted for unique applications. Lapping carriers are available in a variety of materials and thicknesses, including an inventory of more than 20 spring steel thicknesses.

We can create a custom drawing that you can review to ensure the design meets your exact specifications. If you have a drawing or sample part for a lapping or polishing process, PR Hoffman can provide a detailed quotation for your review.

PR Hoffman uses a wide variety of state of the art manufacturing methods to create your lapping carriers including, precision punching, Wire-EDM cutting, CNC machining, CNC routing, and laser cutting. With these options, nearly any lapping carrier configuration is available. We will recommend the most cost-effective method based on your machine and volume requirements.

Carrier Features

- The wafers are afforded greater freedom of rotation with reduced edge damage which helps improve TTV

- 100mm – 450mm Wafer size

- Reduce Cost of Ownership

- Customer Design for your specific application

- ISO 9001:2015 Certified

- Recognized as Worldwide Supplier

- Precision Thickness Control

Spring Steel

Spring steel is the strongest and most durable carrier material. The tightest flatness and thickness tolerances are available in PR Hoffman Steel Carriers.

Cold Rolled Steel

Excellent for thick sturdy parts.

Blue Steel

Primary used for small carriers running thin parts.

Stainless Steel

Perfect for polishing applications that require corrosion free process

G-10 / FR-4

Fiberglass reinforced epoxy. Excellent alternative to steel. Use in applications that prohibit steel but still requires a carrier with strength and durability

Phenolic

Linen, canvas or paper reinforced phenolic resin. Use in processes that cannot tolerate the fiberglass but requires some carrier strength. Best suited for use with oil-based slurries.

PVC

Less costly option for thicker carriers. PVC offers chemical inertness and high strength to weight ratio.

Polycarbonate

Small Carriers for use in nonabrasive environment, reduced strength but also reduces scratching of reinforced alternatives.

Vinyl

Small Carriers for use in nonabrasive environment. Used primarily for short quick runs on small machines.

Insert Carriers

PR Hoffman is recognized as a leading innovator and manufacturer of Insert Carriers, also known as Polishing Carriers, for the semiconductor wafer industry. The insert carrier is an exclusive PR Hoffman design widely used in the semiconductor industry (and other high value wafer industries) to protect the edge profile of the wafer while providing the strength and durability of a traditional steel carrier.

Custom Designs for Semiconductor Processing

PR Hoffman generates a custom drawing for customer review and approval before any products are made. This added service ensures that our customers receive precisely the design needed for their process, on every order.

Our insert lapping carriers significantly improve Total Thickness Variation. Using a unique combination of customized design and high-quality materials, the wafers are afforded greater freedom of rotation, which reduces TTV during the lapping or polishing process.

We offer insert lapping engineering from a variety of different high-grade plastics to meet the widest possible range of processing functions.

With PR Hoffman Insert Carriers, you get:

- Custom designs we create, or we can put your own design ideas to work for you

- Custom materials featuring our own licensed and patented designs

- Carriers molded from proprietary grades and blends of long-lasting polymer

- A wide selection of high-quality spring and stainless steels

- Wafer sizes ranging from 100 mm to 450 mm in diameter

- Used for silicon, sapphire lapping and compound substrate wafers