Polishing Fixtures

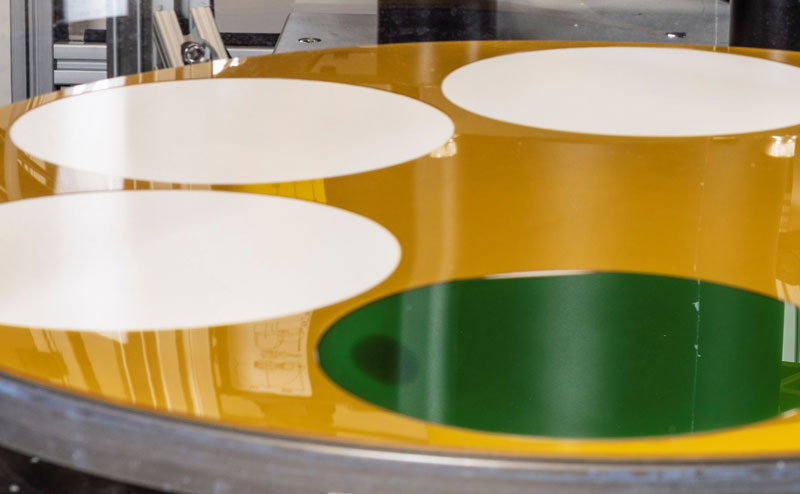

PR Hoffman is a world leader in the design and construction of polishing fixtures. We offer two different styles: the traditional polishing templates and the new patented CXT, chemically resistant templates. Templates and CXTs are uniquely designed to fit each customer’s specific polishing application and environment.

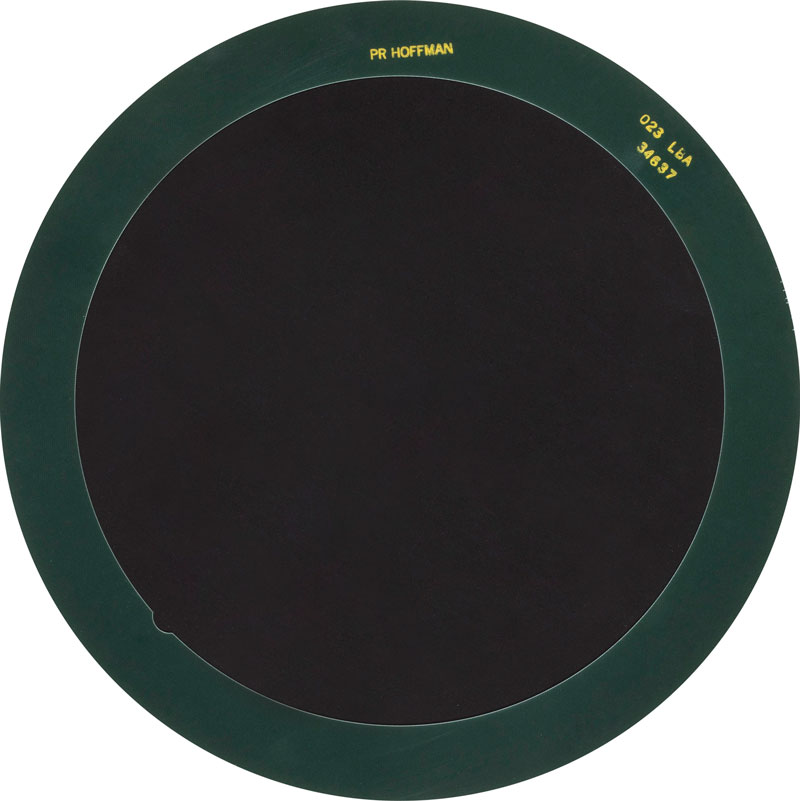

Polishing Templates

PR Hoffman works with each customer to achieve an approved design so you can be sure the template you receive will meet your physical specifications and perform well in your unique processing environment. Templates can be used in any polishing application, flip polish, touch polish, single-side polish, or CMP. This product can help to save both time and money by eliminating the repetitive work required when wax mounting, de-mounting, and then cleaning the wax from the part. PR Hoffman custom manufactures template assemblies for any single-side process such as Silicon wafers, Silicon Carbide (SiC) wafers, compound substrate wafers, glass wafers, ceramics, and glass along with virtually any flat and parallel part that requires a polished surface.

With your basic carrier head dimensions and your material type and size, PR Hoffman can begin the product design process. Other critical parameters include wafer size, hole diameter, wafer final thickness, work hole (pocket) depth, and characteristics of the wafer material.

Each template is backed with a pressure-sensitive adhesive, specifically suited to withstand the effects of the polishing environment. Our templates are assembled in a clean, climate-controlled environment to limit particle contamination. All template edges are milled smooth to prevent particle introduction during the polishing process. The final product is sealed in one-load packages to keep templates clean until use.

Wafer type and polishing environment will help determine the appropriate polishing pad for your application. PR Hoffman offers a variety of polishing pads to fit each application. Our line of pads, when wet, produces the necessary adhesion to hold the wafer in place. To ensure that the wafer stays in place, the custom designed and machined shell is manufactured from the material most compatible with your unique environment. Our shell materials are sourced to provide superior thickness control and optimum surface finish.

PR Hoffman templates are made flat to stay flat. The buffed poromeric and non-buffed materials are backed by a non-absorbent, non-compressible film. The pad stays resilient evenly across the full width of the recess, producing measurably flatter wafers. Every template is lot number identified to ensure full lot traceability after removal from clean packaging. PR Hoffman maintains raw material traceability to production lot numbers for a minimum of 5 years. Each type of fixture lot is fully inspected by our highly trained quality team.

- Flat – All pads are backed by a non-absorbent, incompressible film. The pad stays resilient evenly across the full width of the recess, run after run, producing measurably flatter wafers.

- Long-lasting – Adhesives specifically selected for this application withstand the effects of the polishing process.

- Clean – Templates are assembled in a clean, climate-controlled environment to limit particle contamination.

- Prevent Scratches – All edges of the FR4 template are milled smooth to prevent introduction of glass fibers during polishing.

- Load Size Packaging – Templates are sealed in durable plastic sleeves. Each package contains only enough templates for one machine load to keep them free of contamination until use.

- Easy Installation – The template assembly is backed with a pressure-sensitive adhesive. Just peel away the release paper and press the assembly onto the carrier, per the mounting instructions supplied with each shipment.

- Common Sizes – Template sizes (up to 600mm diameter) for common silicon wafer and other substrates, for single-side polishers using waxless mounting polishers. Templates are completely customer specific so every order is made to the most current revision of the customer specification. PR Hoffman realizes that every customer is not the same and requires their specific custom template.

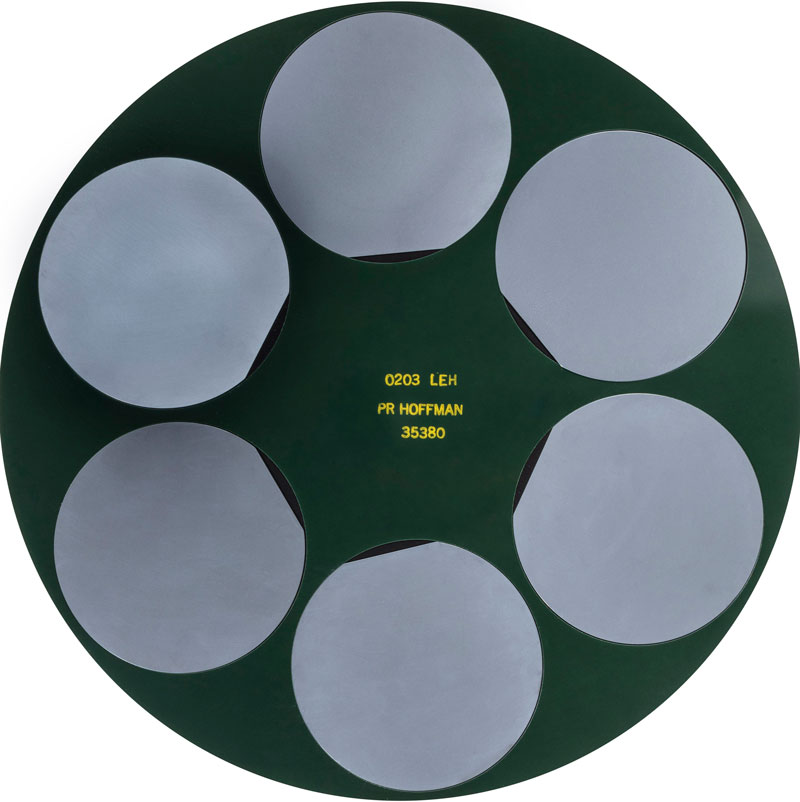

Chemically Resistant Templates (CXT)

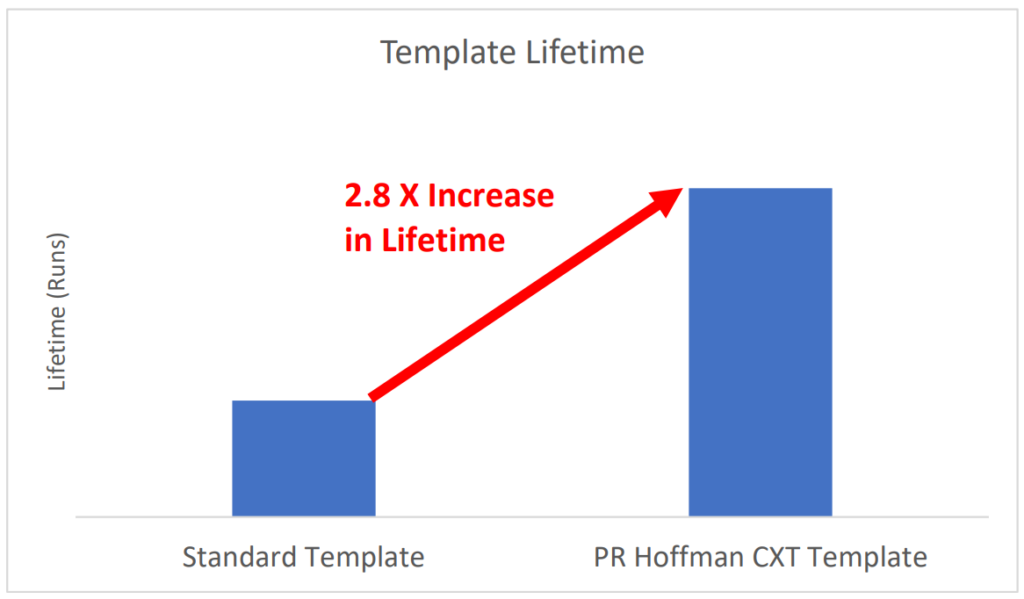

Chemically Resistant Templates, specially designed for harsh environments and the extreme pH levels of slurry for polishing Silicon Carbide (SiC), are the latest innovation in polishing fixtures that PR Hoffman has to offer. CXTs can be used in any polishing application, flip polish, touch polish, single-side polish, or CMP. This product helps to save both time and money with longer lifetime, improve machine and wafer cleanliness, and reduce change over down time. With the seamless single shell construction, it prevents slurry incursion and improves COO. This product has been proven to withstand environmental and processing temperature variations and extreme levels of pH.

Single Shell Construction provides improved COO

- Seamless construction prevents slurry incursion

- Increase template lifetime

- Reduce machine down time

- Fewer template changes

- Reduced carrier head maintenance

- Improved polishing carrier lifetime

Chemically Resistant Pad

- Technologically advanced Chemically Resistant Pad, CRT PAD, designed specifically for the SiC polishing environment

- CRT pad provides a clean process, no pad breakdown to contaminate your slurry or adhere to parts

- Smooth durable shell material

- Unique Barcode Identification included on each CXT

- Customer specific designs all for the uses of this product on any single side polishing carrier head

PR Hoffman begins the product design process by gathering information about your part and processing environment. This will assist in a custom designed product specification drawing. Material type, thickness, shape, along with machine parameters including slurry type, pH levels, machine processing pressures and temperatures all contribute to making the most durable product with the highest quality polished surface. PR Hoffman offers a variety of solutions for your processing parameters, that will result in high quality polished wafers.

Each CXT is backed with a pressure-sensitive adhesive, specifically suited to withstand the effects of the polishing process. Our CXTs are manufactured in a clean, climate-controlled environment to limit particle contamination. All CXT edges are milled smooth to prevent particle introduction during the polishing process. The final product is sealed in poly-bags, per your specific machine load size, to keep templates clean until use. Enclosed barcodes are provided so that your wafer traceability is clear and readable through the entire life of the CXT.

Customers who use the CXT are able to have a pad that is specifically designed for use with SiC wafers and KMn04 based slurries. CXT frames are manufactured using the highest quality raw materials procured to our specific thickness tolerances and dedicated milling equipment to maintain overall product cleanliness and quality.

Converting your traditional template process to the CXT product will improve your overall process cleanliness by eliminating the constant template changes, degrading traditional pads and offering the fast and easy pocket rinse between runs.

Every CXT is lot number identified to ensure full lot traceability after removal from clean packaging. PR Hoffman maintains raw material traceability to production lot numbers for a minimum of 5 years.

Each CXT lot is fully inspected by our quality team and every customer shipment includes a Certificate of Compliance Report that can be delivered electronically to your quality department at the time of shipment.