Chemically Resistant Templates (CXT)

Chemically Resistant Templates, specially designed for harsh environments and the extreme pH levels of slurry for polishing Silicon Carbide (SiC), are the latest innovation in polishing fixtures that PR Hoffman has to offer. CXTs can be used in any polishing application, flip polish, touch polish, single-side polish, or CMP. This product helps to save both time and money with longer lifetime, improve machine and wafer cleanliness, and reduce change over down time. With the seamless single shell construction, it prevents slurry incursion and improves COO. This product has been proven to withstand environmental and processing temperature variations and extreme levels of pH.

DESIGNED FOR SILICON CARBIDE WAFER AND OTHER CHEMICALLY DEMANDING POLISHING ENVIRONMENTS

Single Shell Construction provides improved COO

- Seamless construction prevents slurry incursion

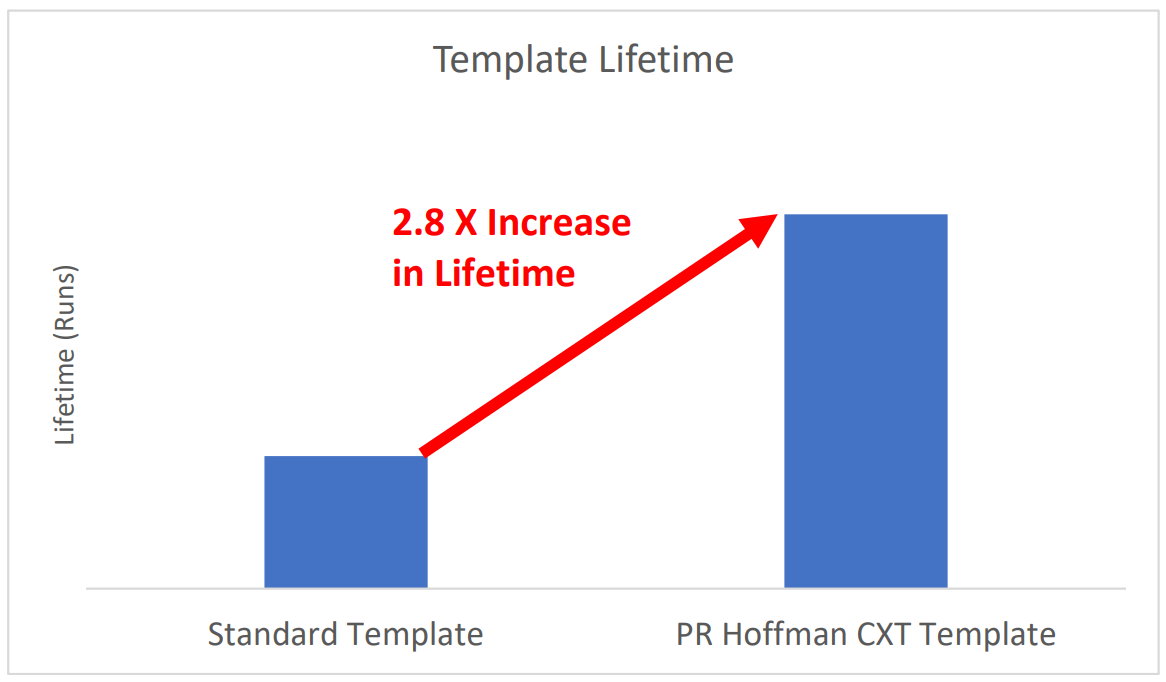

- Increase template lifetime

- Reduce machine down time

- Fewer template changes

- Reduced carrier head maintenance

- Improved polishing carrier lifetime

Chemically Resistant Pad

- Technologically advanced Chemically Resistant Pad, CRT PAD, designed specifically for the SiC polishing environment

- CRT pad provides a clean process, no pad breakdown to contaminate your slurry or adhere to parts

- Smooth durable shell material

- Unique Barcode Identification included on each CXT

- Customer specific designs all for the uses of this product on any single side polishing carrier head

Design

PR Hoffman begins the product design process by gathering information about your part and processing environment. This will assist in a custom designed product specification drawing. Material type, thickness, shape, along with machine parameters including slurry type, pH levels, machine processing pressures and temperatures all contribute to making the most durable product with the highest quality polished surface. PR Hoffman offers a variety of solutions for your processing parameters, that will result in high quality polished wafers.

PR Hoffman begins the product design process by gathering information about your part and processing environment. This will assist in a custom designed product specification drawing. Material type, thickness, shape, along with machine parameters including slurry type, pH levels, machine processing pressures and temperatures all contribute to making the most durable product with the highest quality polished surface. PR Hoffman offers a variety of solutions for your processing parameters, that will result in high quality polished wafers.

Each CXT is backed with a pressure-sensitive adhesive, specifically suited to withstand the effects of the polishing process. Our CXTs are manufactured in a clean, climate-controlled environment to limit particle contamination. All CXT edges are milled smooth to prevent particle introduction during the polishing process. The final product is sealed in poly-bags, per your specific machine load size, to keep templates clean until use. Enclosed barcodes are provided so that your wafer traceability is clear and readable through the entire life of the CXT.

Materials

Customers who use the CXT are able to have a pad that is specifically designed for use with SiC wafers and KMn04 based slurries. CXT frames are manufactured using the highest quality raw materials procured to our specific thickness tolerances and dedicated milling equipment to maintain overall product cleanliness and quality.

Quality

Converting your traditional template process to the CXT product will improve your overall process cleanliness by eliminating the constant template changes, degrading traditional pads and offering the fast and easy pocket rinse between runs.

Converting your traditional template process to the CXT product will improve your overall process cleanliness by eliminating the constant template changes, degrading traditional pads and offering the fast and easy pocket rinse between runs.

Every CXT is lot number identified to ensure full lot traceability after removal from clean packaging. PR Hoffman maintains raw material traceability to production lot numbers for a minimum of 5 years.

Each CXT lot is fully inspected by our quality team and every customer shipment includes a Certificate of Compliance Report that can be delivered electronically to your quality department at the time of shipment.